DFA, DFM AND DFT

In collaboration with the customer, we offer engineering solutions to improve the final product and identify opportunities to reduce the cost of materials in the manufacturing and testing process and improve testability

How we do it?

From start to finish for you.

In collaboration with the customer, we offer engineering solutions to improve the final product and identify opportunities to reduce the cost of materials in the manufacturing and testing process and improve testability

This is an added value to our range of services, providing in-depth knowledge of the industry, manufacturers and distribution lines, as well as market developments and cost savings.

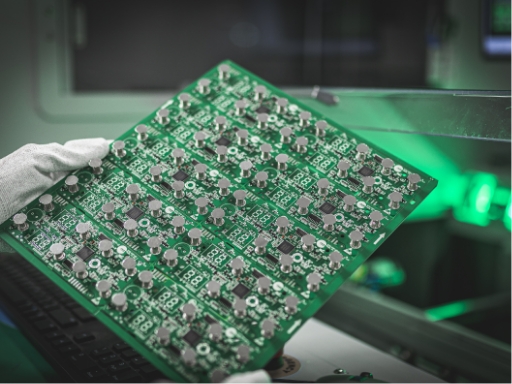

We assemble first samples to evaluate, correct and improve the industrialization process according to the requirements of our customers, qualifying the manufacturing process and controls before going to mass production.

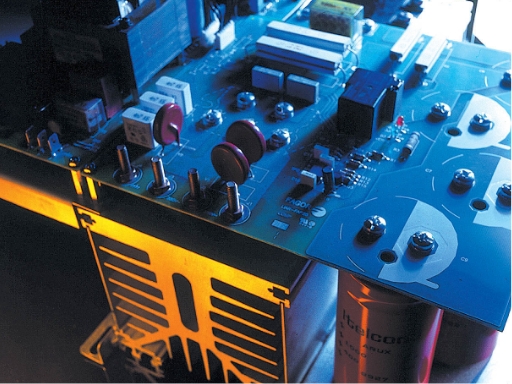

Fagor Electrónica offers a wide range of possibilities that include the assembly of PCBAs with different assembly and soldering technologies. Automatic assembly from SMT to THT; different soldering technologies such as nitrogen reflow, selective and wave soldering, hot bar, test, SPI 3D in-line, AOI 3D, ICT and FCT in-line and off-line, coating and potting, developed according to our customers' needs and market requirements.

An advanced component laboratory and burn-in means, as well as humidity and temperature climatic chambers, shocks and thermal cycles, for product, allow us to ensure excellent reliability to all our products.

The process does not end with the manufacture of the product, from Fagor Electrónica we assure an integral service, for that reason we deliver the product where our clients need it.

We have the circuit for your specific needs

We manufacture electronic circuits for electric windows, consoles, switches, control knobs, ambient and ceiling lighting for a wide range of vehicles.

Our experience is backed by IAFT 16949 certification and homologation by the main car manufacturers and TIER-1

Design, development and manufacture of equipment for the distribution of telecommunications services in the infrastructure of buildings and homes.

We develop circuits for power electronics applications, mainly focused on electronic control cabinets and inverters.

From Fagor Electrónica to thousands of homes. We create the electronics for a diversity of household appliances. From touch controls for induction hobs and/or glass-ceramic hobs, to electronic controls for washing machines or refrigerators; among many other things.

Our commitment to the environment is also reflected in the electronic products we manufacture for renewable energy companies, mainly for photovoltaic and solar thermal systems.

Inverters in the aeronautical sector are becoming more and more necessary, that's why in Fagor Electrónica we make electronics and sensorization of circuits for this sector.

In 1993 we obtained the ISO 9001 Quality Certificate. From 1995, in Fagor Electrónica we adopted the European Model EFQM as a management reference model, and so, in 1998 with the Silver Q for Business Excellence.

Currently, both in our Mondragon plant and in Thailand, we have the IAFT 16949 certificate for the automotive sector. Likewise, our plants are approved by the main manufacturers and TIER 1 in this sector.

Sensitivity to the environment is also an ingrained value in the company, which thus further expands the quality offer at all levels. The result of this is the achievement in 2002 of ISO 14001 Certification at the Mondragon plant and in 2014 at the plant in Thailand. Quality is implicit in our way of doing things.